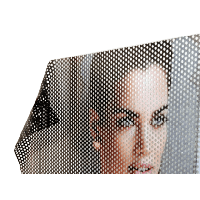

How Perforated Window Vinyl Works

Have you ever wondered how drivers can see through the window of a vehicle that is fully covered with a specific film decal? A material used for this purpose is called perforated window vinyl and is widely applied on public transport, commercial vehicles, bus stops, showcases, etc. Perforated window vinyl provides the one-way vision to see the outside when you are indoors easily. It happens due to the film's structure that contains about 50% small holes. In this article, we'll discuss everything you need to know about perforated window vinyl for cars.

What is perforated vinyl?

Perforated window vinyl, also known as one-way vision film or see-through vinyl, is adhesive-backed PVC vinyl that incorporates a specific pattern that contains small holes. The ratio of vinyl to tiny holes is approximately 50\50, but it can fluctuate. Considering the unique structure of this material, perforated vinyl allows visibility for people inside the vehicle.

Perforated window vinyl offers a range of promising benefits.

First, vinyl material is highly durable, resisting multiple external factors. It can be used for outdoor purposes easily. Next, images or designs printed on this material are quite bright and attractive, so make sure your advertisement or promotion will be eye-catching. It is worth mentioning that perforated vinyl is an affordable material – even campaigns with a small budget will reach success. One more important thing – once placed on the windows, this kind of vinyl ensures the best visibility and reduction of UV radiation, as well.

How to print perforated vinyl

Perforated window vinyl printing is easy to perform by using a printer with white ink. General rules for printing are minimizing the amount of ink and evaluating test prints. Here are some essential tips for printing on perforated vinyl.

1. Design

It is essential to utilize minimal ink loading and avoid printing oversaturated copies. In practice, a structure of perforated vinyl will consume some percentage of pictures. Don't compensate for the lost part of contrast since it will be restored in certain light conditions.

2. The white and black layer

The white printing layer is needed for making the design visible from the panel. Total opacity isn't an obligation, but a white layer should block the black one from showing through it. On the other hand, a black layer provides light-absorbing so you can view through the applied graphics. In use, it can be reached at the expense of lightweight pure K black ink that is printed as a protective barrier. Don't omit the test printing to make sure white and black layers look correct.

3. Test printing

This tip is helpful to assess the properties of perforated window vinyl in determining conditions. A colorful image should be seen with a clean highlight and no bold details in shadow from the print side. From the other side, no details should be seen, apart from the slight shadow that appears via the ink accumulation on the edges of the holes. After printing, leave a print to cure before you remove the liner fully.

How to apply perforated window vinyl

Whether you decide to apply perforated window vinyl on a large area, don't expect to do this task independently. Have one companion to assist you while using for a film. Here are some essential tips on applying a decal on a surface quickly and effortlessly.

- Stock up with scissors, a knife, a felt squeegee, and adhesive tape for applying your perforated window vinyl.

- The first step is cleaning the surface of any dirt. Make sure you remove all grease from a glass surface before sticking a decal.

- Glue the perforated vinyl on a surface from top to bottom until it is aligned enough. For this purpose, utilize a felt squeegee and move it from a center to the edges of a decal to remove all the air bubbles.

- Next, use a washable marker to mark the window or other surface.

- You need to remove the protective layer of a film, and after it, you will see the black adhesive side of a decal.

- Align your perforated vinyl with the marks you made before, and use scissors or a knife to cut the excess material from the edges.

What temperature is needed for working with perforated vinyl

Generally, most self-adhesive vinyl, including perforated ones, provides a minimum temperature for the application, so the installation at low temperatures can make it challenging to apply. If the temperature is below minimal, the glue can become challenging, changing the sticking properties of vinyl. The average temperature to work with a perforated vinyl is about 10 degrees Celsius.

What window perforated vinyl should you use on a vehicle?

Before using perforated vinyl on your car, make sure it suits vehicles at all. Essentially, drivers often apply window decals and perforated vinyl film on car windows, but they provide several differences. Decals, incredibly transparent designs, can be used for the vehicle's windows. Still, herewith, you won't be able to see from a distance as the limited visibility will prevent you. Unlike window decals, perforated window vinyl offers excellent visibility for drivers but simultaneously limits the ability of people to see inside a vehicle.

Perforated window vinyl is an excellent tool for advertising since your car window graphics will be bright and attractive, providing 24\7 brand promotion. The complete customization of perforated window vinyl gives you a great chance to show off your business, too. While ensuring you the excellent «moving» advertisement campaign, perforated vinyl material is also great for window tinting. This way, you can achieve some privacy inside your car since people won't see what is in the car while looking at a decal.

Perforated vinyl printing provides:

- Full customization.

- Excellent visibility for drivers.

- Weather resistance makes this material ideal for advertising on car surfaces.